Expert’s Thoughts

"Businesses have thoroughly considered the ways of processes automation and optimization, since the Covid-19 pandemic. The unparalleled growth of AI became an additional signal for companies to reconsider traditional operational practices.

Silk Data has already presented comprehensive overviews on AI agents, AI avatars and other artificial intelligence and outsourcing solutions that can change the landscape of business operations.

This blogpost covers the topic of how RPA in manufacturing can be beneficial and how its integration with AI technologies leads to greater business operational efficiency."

Yuri Svirid, PhD. — CEO Silk Data

RPA in Manufacturing. New Stage in Processes Automation.

Robotic process automation is not an entirely new technology as its practical displays have existed for years already.

The industry faced its turning point in 2019-2020 when the global business had to find new operational practices and align to the new conditions of Covid-19 pandemic. Since then, the RPA has demonstrated rapid growth, and more companies tend to implement it into their internal processes.

Comprehensive research made by Fortune Business Insights provides several facts regarding the industry development:

The RPA market size reached 22,5 billion USD in the first quarter of 2025.

The annual market growth is expected to be 18% with the market size of 73 billion USD reached by 2032.

Main RPA use cases are Advanced Analytics, Customer Support, Administration and Reporting and Data Migration.

By region, North America remains a leader on the global RPA market.

There are lots of reasons why companies all around the world decided to reconsider their operational practices and choose robotic process automation in manufacturing as one of the methods.

The following blogpost provides an overview of these reasons, examining the essence of RPA, the benefits it gives, the most popular use cases along with the data on how AI influences the automation industry.

What is RPA?

RPA or Robotic Process Automation is an operational and automation technology that uses software bots (‘digital robots’) to perform repetitive, rule-based and low-level tasks without human intervention. The main trait of such digital bots is that they are developed to mimic the way humans interact with digital systems.

In its essence, RPA bots base their actions on sets of rules defined by users. When the bot is implemented, its training is based on providing it with the information on user’s actions within a software, app or API. The information can be presented in the form of screen records (like button clicks or data copying and entry performed by a user) or as an above-mentioned set of pre-defined rules.

The process of RPA implementation and usage can be divided into several key stages:

- The company identifies repetitive and labor-intensive tasks of high frequency within its operations (for example, entering data from PDF invoices into corporate database).

- The RPA is configured by the user, a human supervisor, who ‘trains’ it on performing specific tasks in a specific manner.

- The bot logs into the company’s digital system and performs tasks it was configured for.

- The bot shares activity data with human specialists or notifies them on the problems.

In other words, RPA is a technology that allows to fully delegate painstaking, repetitive tasks to a primitive machine to ensure low-level automation in manufacturing. The scales of such a delegation can differ according to the scales of the business’s internal operational system, as there can be hundreds of bots deployed within company workflows, each responsible for certain tasks.

It’s worth noticing that RPA implies the usage of low-code tools and works at UI level, which dramatically increases the speed and ease of deployment, if compared to traditional automation practices (such as scripting, enterprise application integration or database automation ).

However, to successfully implement RPA, it is necessary to clearly define internal workflows and use special RPA software. RPA also can be presented by attended bots (that work directly alongside humans) and unattended bots (that run backend tasks that work seamlessly for employees). Moreover, RPA solution is limited by its inflexibility to UI changes and poor scalability capabilities.

Industries of RPA Usage

Banking and Finances

The sphere of banking and finances has one of the highest amounts of low-level operations (about 30% of the entire workflow consists of data copying and transfer, invoice management and other routine tasks).

Usage of manufacturing automation technology optimizes and speeds the labor-intensive and repetitive processes up, reduces the number of errors and ensures compliance.

It can be achieved through automated banking accounts opening and closing, claims invoices and applications processing and transactions management and reconciliation .

For example, Paramount Residential Mortgage Group (PRMG) — mortgage banker that operates across all the United States implemented 6 bots, each of them focuses on a particular step of loan processing.

As a result, PRMG reduced the time of processing by 600% and now saves about 2 million USD every year.

Additionally, recent research by Gartner claims that 80% of leading financial companies implemented RPA or plan to do so in the near future.

Healthcare and Insurance

RPA also provides great advantages in data handling, processing time optimization and data migration which are vital for the healthcare industry.

According to the TechTarget research of December 2023, 43% of CFOs and revenue cycle leaders in US hospitals use RPA to automate revenue cycles, while 80% of those who don't use automation said that they are about to do this by the end of 2025.

The RPA’s ability to mimic human actions can be crucial for the tasks regarding applications processing and patients’ registration and management. For example, bots are used in automated data extraction from PDF, scanning and hand-written forms and reports. The combined usage of bots and OCR technology allows to cut the time spent on unstructured data processing by 65% on average.

As a result, healthcare specialists can be relieved from hours of their working time spent on repetitive and painstaking tasks (like doctor/patient appointment management, potential insurance client applications processing and many others).

A bright example of robotic process automation in healthcare was presented by Pain Treatment Centers of America (PTCoA). The usage of multiple bots allowed to increase efficiency of the patient claims processing. The implemented solution allowed bots to handle and automate processing of payment adjustments and approvals, price comparison, lab order management processes and much more.

Manufacturing and Procurement

RPA usage can be beneficial for manufacturing and procurement industry as well.

Procurement and manufacturing organizations can optimize the processes of supply chain tracking through automated shipment statuses updates or speed up the customer queries management via invoice matching and management.

RPA bots can automate vendor queries processing, management and transfer. Additionally, they can autonomously work with both corporate and customer reports.

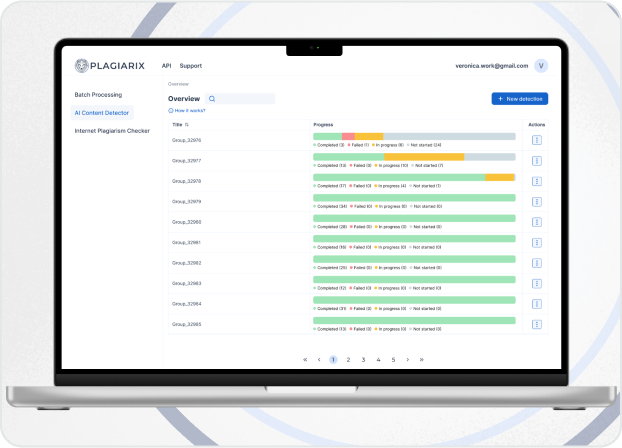

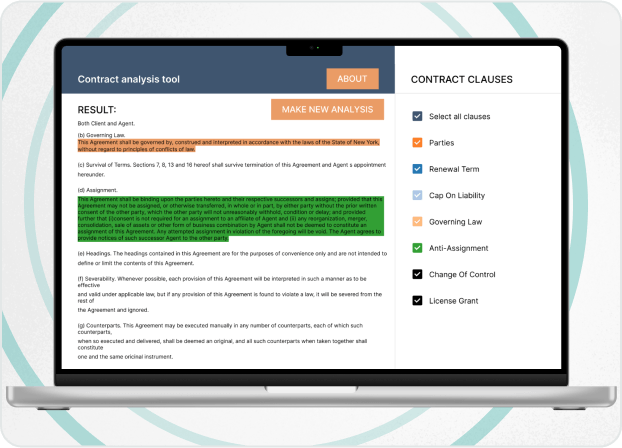

Silk Data team has successfully implemented a solution that allowed a procurement company to increase the efficiency of dealing with customer invoices through automated data extraction processing.

The solution was even more efficient, compared to traditional RPA practice, as it leverages advanced capabilities of ML and AI technologies.

Retail and E-Commerce

The main benefit that retail companies can get from RPA implementation is to scale operations and relieve specialists in periods of excessive workloads .

For instance, RPA bots can be configured to perform order processing or goods info management or returns handling. From the point of marketing, RPA can be used for extracting and sharing data from market research reports or adding it to corporate database.

Additionally, manufacturing automation in retail provides 24/7 support for both customers and internal systems. A good example is a Supermarket chain — a mobile application developed by Silk Data for a top German retail corporator. Our solution reduced the time spent on maintenance by 30% and allowed the company to achieve 38% increase in the implementation of loyalty programs and 23% increase of customer retention.

IT and Communications

For the IT and telecommunications industry, RPA is extremely useful when it comes to customer support or new users onboarding.

Being integrated into CRMs or other corporate software, bots can automate the notification processes, autonomously perform data sharing or activate accounts and services.

Additionally, RPA tools can be configured to monitor alerts and system errors and automatically response to them or notify specialists.

As an example of RPA usage in telecommunications, we can present a case by GPS nVISION — a company from Texas specialized on devices and software for cars, assets and people tracking. Implementation of low-code RPA solution allowed to shorten the time spend on executing device and SIM cards activation and deactivation by 400%. It was achieved through permanent requests monitoring and users accounts’ automated configuration.

See prospects of optimizing your workflows through RPA? Get in touch and our manager will identify the key points of possible RPA implementation.

RPA in Manufacturing Key Benefits

Cost optimization

Usage of RPA tools is one of the steps to business’s cost-reduction strategy.

Delegation of painstaking repetitive tasks to a machine not only saves dozens of specialists’ working hours every month but also appears to be the cheapest solution.

According to the research by Gartner made in late 2024, RPA bot implementation is 3 times cheaper than the work of offshore employee and 5 times cheaper than the work of onshore employee. It means that even delegating routine work to outsourcing companies is not so effective from the point of cost optimization, compared to RPA.

Increased productivity

Delegation also means that company’s specialists will be able to focus on tasks critical for business, instead of spending hours on monotonous operations. The practice of mass RPA implementation allows to eliminate the disturbing factor of manual operations on low-level tasks.

According to predictions made in Grand View Research report, by the end of 2025 RPA will eliminate more than 40% of manual corporate service desk operations and engagements. Through that, the efficiency and productivity of employees can dramatically grow without additional expenses and risks of quality downfall or mass burnout of specialists.

Moreover, RPA tools can manage operations 24/7, so better operational security and higher availability are possible.

Better quality and accuracy

In addition to cost reduction and better productivity, usage of RPA guarantees increased quality of corporate operations.

Usage of machines eliminates the human factor, when mistakes can be made because of exhaustion, lack of time or any external disturbances.

In some cases, consistent and efficient performance of repetitive tasks can be crucial for business, and RPA to make you confident of 100% accuracy.

Optimized resources distribution

All three above-mentioned factors lead to the main benefit of RPA usage – optimal allocation of corporate resources.

RPA’s capabilities of processes automation and optimization allow to shift employees from repetitive work to strategic work, reduce operational costs and transfer budgets to other tasks or notify specialists on problems occurred.

AI and RPA. New Era in Automated Manufacturing and Operations

Though robotic automation provides lots of advantages for businesses to leverage it, traditional bots have several limitations.

Struggling to work on complex tasks and decisions

Primitive RPA bots lack any reasoning or self-learning capabilities, so it is difficult to configure them on dealing with medium- or high-level operations.

Being not a complete IT solution

Though bots are good at solving simple, repetitive problems, they are not fit to work on system redesigning or deep processes optimization.

Based on static rules

As RPA’s work is based on pre-defined rules, the system lacks flexibility and can’t properly operate if the app, software or API has been changed or updated.

In other words, traditional RPA is a cheap and easy-to-use solution, until you need more advanced processes optimization.

The key solution is to combine RPA with AI development . For the past years, the industry has seen a clear tendency of AI implementation in RPA-based processes.

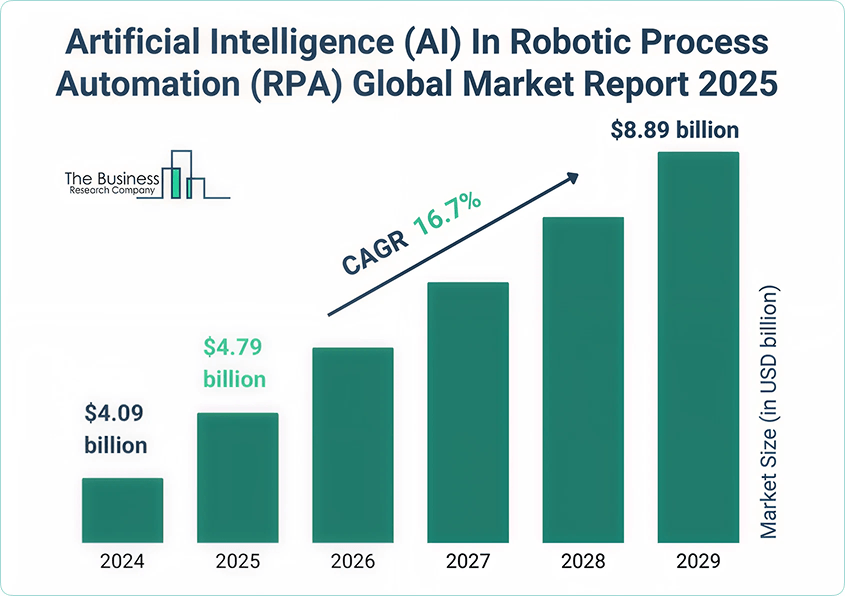

According to a recent Business Research Company report , the AI RPA market size has reached 4,8 billion USD in 2025 with an annual growth rate of 17%. It means that the market size will double by 2029.

Source: https://www.thebusinessresearchcompany.com/

The main purpose of using AI technologies in RPA is to use the capabilities of AI in order to improve efficiency, scalability and adaptability of robots.

Leveraging AI allows to bring the RPA to a new level through several advanced improvements.

AI-based tools can learn from historical or current data and make predictions regarding operational efficiency and possible problems.

Self-learning

AI allows RPA bots to track system changes and align its actions to new surroundings (such as new UI or API configuration).

NLP-based operationing

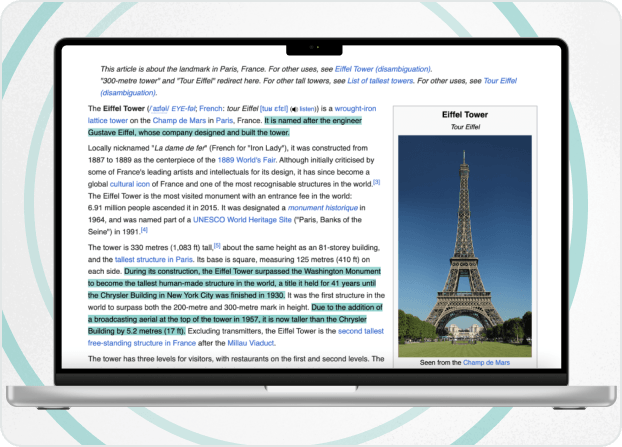

By leveraging Natural Language Processing technology, RPA tools can improve their capabilities of working with unstructured data ( textual documents, emails, hand-written forms ) which is crucial for industries like customer support, manufacturing and procurement.

Conclusion

The manufacturing industry stands at the forefront of a transformative shift, where RPA is no longer just an option — it’s a necessity for staying competitive. As businesses continue to adapt to an AI-driven future, RPA has emerged as a key enabler of cost savings, productivity gains, and operational resilience.

However, the true game-changer lies in integrating RPA with AI. While traditional RPA excels at structured tasks, AI-powered RPA brings cognitive automation, enabling bots to handle unstructured data, predict maintenance needs, and even adapt to system changes in real time.

But the key thought businesses should consider is that automation is not about replacing humans — it’s about empowering them to focus on what truly drives growth.

Our Solutions

We work in various directions, providing a vast range of IT and AI services. Moreover, working on any task, we’re able to provide you with products of different complexity and elaboration, including proof of concept, minimum viable product, or full product development.